Cason | C90 Aerobic Vertical Fermentation Machine

| Categories | Manure Fermentation Tank |

|---|---|

| Brand | Cason Breeding equipment Manufacturer |

| FOB port | QINGDAO PORT |

| Terms of Payment | L/C, D/A, T/T, Paypal |

| Update Time | Dec 21,2024 |

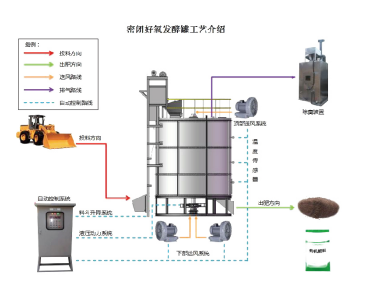

C90 Aerobic Vertical Fermentation Machine

- Qingdao Zeyu Kaisheng Machinery Manufacturing Co., Ltd. is a professional manufacturer and supplier of CASON® Japanese aerobic vertical fermentation machine. Qingdao CASON® has the ability to serve the whole process from environmental protection scheme design to aerobic vertical fermentation machine installation, and has a long-term deep cooperation with state-owned enterprises, central enterprises, listed groups, and foreign customers, to provide them with complete environmental protection system overall solutions.

Product Description

- CASON® fermentation enter (vertical aerobic fermenter) is an all-Japanese high-end fermentation system, Compared with the traditional fermentation mode, the fan oxygen transmission and thermal insulation effect is good; Half half fermentation time, Equipment covers a small space, Reduce the land utilization rate.

1. Product Introduction

- C90 Aerobic Vertical Fermentation Machine is a fermenting machine for the purpose of decomposing organic waste while evaporating the moisture in the raw material to obtain excellent organic fertilizer by the living movement of microorganisms.

C90 Aerobic Vertical Fermentation Machine shall not use sawdust, wood chips and other moisture-adjusting materials to dry the high-moisture raw materials while aerobically fermenting them at high temperature.

- Aerobic high-temperature fermentation treatment is an environmentally friendly and efficient way to obtain high-quality organic fertilizer by saving energy. In order to promote aerobic fermentation, the following conditions need to be present.

- (1) Moisture content.

- (2) Air.

- (3) Temperature.

- (4) PH value.

- (5) Carbon to nitrogen ratio.

- The above conditions need to be adjusted appropriately

- Must not contain chemicals that hinder the reproduction of high temperature strains.

- To achieve homogeneity of the product and to speed up drying, the air supply system needs to continuously feed the appropriate air volume. The above matters are necessary.

2. C90 fermentation tanks structure

C90-A | |

|---|---|

Project | Specification |

Total capacity of fermenter | 87.5m³ |

Hopper capacity | 1.5m³ |

Sold weight | 26t |

Electricity | 50Hz |

1. Upper air supply blower (imported) | 1.9kw |

2.Downward air supply blower (imported) | 8.7kw*2 |

3.Electric heater(for emergency) Optional | 5.0kw |

4.Oil pressure motor | 7.5kw |

5. Feeding port motor | 0.75kw |

6.Hopper lifter | 2.2kw |

7.Exhaust blower | 4kw |

Total | 38.75kw |

Total when electric heater is not used | 33.75kw |

Processing capacity(processing capacity deviates according to season and region) | |

C90-B | |

|---|---|

Project | Specification |

Total capacity of fermenter | 87.5m³ |

Hopper capacity | 1.5m³ |

Sold weight | 26t |

Electricity | 50Hz |

1. Upper air supply blower (imported) | 2.2kw |

2.Downward air supply blower (imported) | 11kw*2 |

3.Electric heater(for emergency) Optional | 5.0kw |

4.Oil pressure motor | 7.5kw |

5. Feeding port motor | 0.75kw |

6.Hopper lifter | 2.2kw |

7.Exhaust blower | 4kw |

Total | 43.65kw |

Total when electric heater is not used | 38.65kw |

Processing capacity(processing capacity deviates according to season and region) | |

3. Preparation of strain (amount of seed fertilizer)

- Please follow the quantities in the table below (actual volume of fermenter*80%)Unit :m³

Machinery category | Amount of bacterial bed(seed fertilizer) |

|---|---|

C90-A | 69m³ |

C90-B | 69m³ |

- Increase or decrease bedding materials according to the actual conditions of the raw materials on site.

4. High-moisture raw materials(internal changes)

- Please follow the quantities in the table below(actual volume of fermenter*80%) Unit:m³ Example:70-85% moisture

- 1. Every day, add 4 m³ of raw material with high moisture content

- 2.1.3m³ of product is removed each day

- 3.the number of days of fermentation from the time of adding raw materials to the time of removing products is about 16 days

- Tel

- *Title

- *Content

- KEEP UP TO DATE

- Sign up for our newsletter and follow us on social media

CASON MACHINERY

CASON MACHINERY